There are many types of prefabricated structurally insulated panels (SIPs) available. The most common have a core of expanded polystyrene (EPS) insulation sandwiched between OSB sheathing. They are built and cut to size in a factory, including openings for windows and doors, and are shipped to the job site ready for installation. Factory production and the use of engineered and recycled wood products offers the potential for a more precise product, less waste, a speedy job site build, and lower embodied carbon.

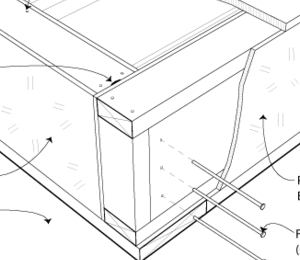

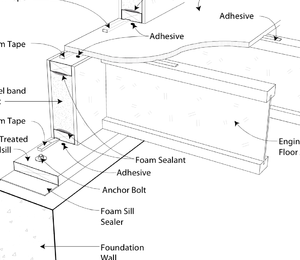

As the name implies, SIPs can be structural, and used for both walls and roofs, or they can be combined with timber frame, or post-and-beam construction, where appropriately sized posts, beams, and trusses carry the structural loads. This allows for fewer studs in the panels, which reduces thermal bridging and increases the overall R-value of the system. Panel joints are glued and taped and installed to create an airtight building assembly. As with all tight buildings, homes constructed using SIPs cannot rely on passive ventilation and must have well-designed active ventilation systems.

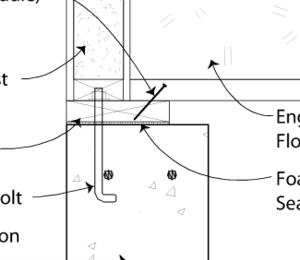

The use of SIPs results in faster construction on site but requires careful planning ahead of time involving all trades. The placement of windows, HVAC systems, plumbing and wiring must be designed ahead of time as changes later will be costly and complicated. Therefore, the decision to use SIPs needs to be made early in the design process so all these details can be worked out before the panels are fabricated. With tapes and sealants used at all joints, SIPs are their own air barrier, so proper installation is imperative.

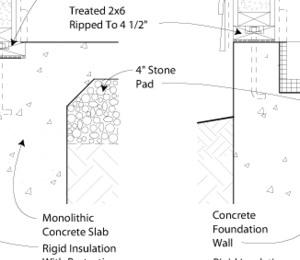

The high degree of accuracy of factory-built SIPs results in little forgiveness when installed. The foundation must be perfectly square and level, otherwise the corners of the building will not come together properly, which will affect…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in