Image Credit: Scott Gibson

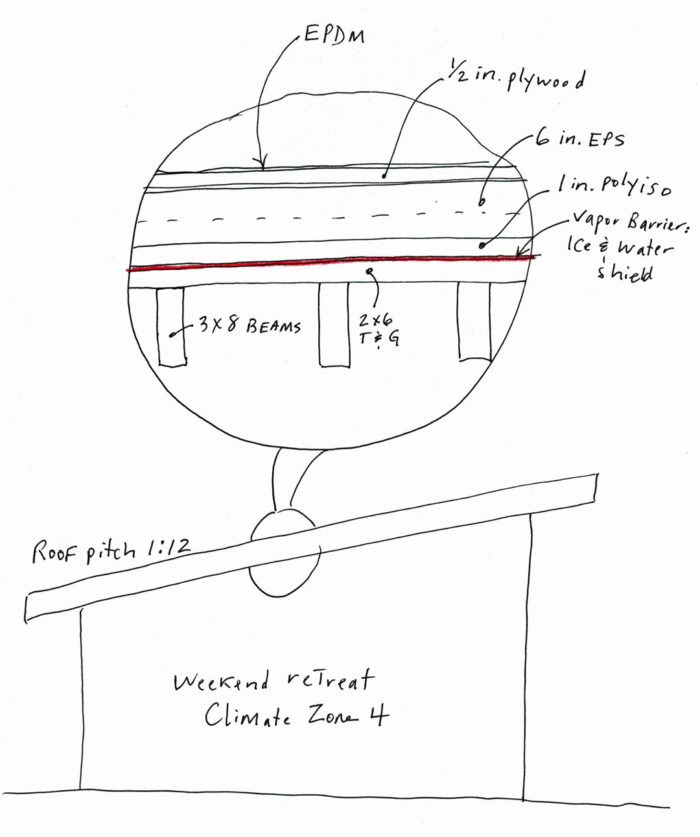

Plans are taking shape for Quinn Sievewright’s holdiay home: a small retreat with a shed roof that will be built in Climate Zone 4 near Vancouver, Canada. During the winter, the building won’t be occupied full-time, but enough so that Sievewright has included several layers or rigid foam insulation in the design for his low-pitch roof. (The drawing at right shows how he’s proposed to build it.)

Inside, the roof assembly will include exposed 3×8 Douglas fir beams topped by 2×6 tongue-and-groove boards. That’s followed by two or three layers of rigid foam insulation, plywood sheathing, and EPDM or another type of membrane roofing.

“The house designer (not necessary a qualified architect or experienced builder) says we need Ice and Water Shield for ice dam protection,” Sievewright says in a Q&A post at Green Building Advisor. “I fail to see in what layer of the build-up that would go in the ‘warm,’ unvented assembly we are proposing, and what it would achieve when one has a fully-adhered type roof like an EPDM membrane.”

Sievewright says that he recognizes that the air seal would typically be located on the bottom of the rafters, but that won’t be possible with the construction he’s now considering.

“The open-rafter architecture is beyond my control but is commonly done, even though it’s perhaps not the ideal method,” he writes. “As such I am trying to come up with the best solution.”

Has he? That’s the topic for this Q&A Spotlight.

The roof plan is problematic

Ice & Water Shield is a brand of peel-and-stick membrane made by GCP Applied Technologies. It’s commonly used in roof assemblies, particularly in snow country and areas where wind-driven rain is a problem. It’s usually applied directly to roof sheathing.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

9 Comments

Ice dams? In Vancouver B.C.? Why is that even a topic?

Seriously folks, there's never enough persistent snow in zone 4C to be concerned about ice dam issues! The mean monthly temperature even for January in Vancouver is well above freezing a ~ +39F, (even the average daily LOW in January is above freezing), and fallen snow only rarely persists for more than 3-4 days. Snowfalls of a foot or more are once or twice per decade type events.

A bigger issue for low slope roofs in that temperate rain forest type climate is keeping the roof deck dry enough to avoid heavy moss growth given the limited number of sunny hours and high number of active rain hours. Vancouver is overcast more than 50% of the time, and overcast to mostly cloudy ~70% of the time from early November through late March, getting very little solar assist for drying the roof, ventilated or not.

Response to Dana Dorsett

Dana,

When I first read your comment, I thought the blunder might have been mine (due perhaps to my Vermont-centric approach to building).

A quick check revealed the truth: it was Quinn Sievewright's designer, not anyone involved with GBA, who raised concerns about possible ice dams.

I think you're right about snowfall in Vancouver.

-- Martin Holladay

Moss

Since Dana brought it up, I was curious:

Are there any problems caused by moss growth?

It's like you're getting a green roof for free! ;)

The moss is one of my favorite thing about the pacific northwest.

Vancouver and environs

Yes you can often golf in January, but Vancouver is right up against the Coast Mountains. Within fifteen minutes of the municipal boundary there is a ski resort. North Vancouver borders an recreational area with the most active wilderness rescue team in Canada, where hikers die in avalanches on a regular basis. The problem is more likely that Quinn used the wrong climate zone to describe the location of his cottage that that he shouldn't worry about ice dams.

However, his designer's comment probably has more to do with the building code than anything. It requires eave protection against ice dams everywhere without making exceptions for the mild coastal climate.

Add strapping?

Hello again

Thanks for featuring this question - hopefully it helps future readers.

I've got an additional question if I may, more construction practicalities related but with a building science implication....

The contractor would like to add some 1x4 strapping perpendicular to our underlying 4x8 beams (beams installed on 48" centers, strapping would perhaps be 24" centers) above the rigid foam. He wants to do this to ease the installation of the overlying ply so that only the strapping needs expensive long screws to penetrate the rigid foam and the ply can be installed with short screws penetrating just the strapping and countersunk flush (long screws seem to all have large heads which would show through on the overlying EPDM).

We could fill the space between the strapping with additional insulation (approx 3/4" for 1" nominal strapping) or just leave it as an "air gap" linked to soffit vents, or not vented at all. I gather the 'venting' wouldn't be needed in this assembly to address moisture build up from internal sources, but wasn't sure if it might help in summer as the black EPDM will get quiet warm? Perhaps not though.

As always, your advice greatly appreciated.

Quinn

Response to Quinn Sievewright

Quinn,

The contractor's plan will work, as long as an engineer approves the type of fastener, and the length of the fastener, used to hold down the 1x4 strapping. Those fasteners are being asked to do a lot of work, so they had better be right for the assembly to work.

The air gap is a benefit, not a problem. It can be vented or not, as you prefer.

Mold on strapping material

Hello all,

We are a few weeks in on this build and so far the crew have been great at embracing the Zip wall systems and thinking about air sealing and thermal bridging etc as we progress.

The roofing materials have arrived and the 1x3 untreated strapping has arrived but is very moist and covered in black and white mold spots. Clearly the lift has been left out in the rain and been covered with a tarp or something to prevent drying. I've spread it out to dry in the sun but I'm concerned about introducing this mold into the roof assembly. Should I be concerned? Or is the material perfectly fine to use? Thanks!

Response to Quinn Sievewright

Quinn,

Mold on lumber isn't that unusual. You have the right idea -- the lumber needs fresh air and sunshine, with breezes.

As long as it isn't sopping wet when it is installed, everything will be fine. A few black stains won't cause any problems.

All,

I have 2 roofing questions for a flat unvented roof assembly in San Francisco (very humid but not that cold) house with an interior de-humidifier and ERV.

(fwiw: Cost is a factor)

Assembly (out to in): EPDM; on top of ZIP-R-9 [Q1: or regular plywood on top of equivalent polyiso foam?]; on top of 1/2" plywood on top of joists w/ Fiberglass in rafter bays (r30); on top of

level 2 Drywall [Q2: or cheaper/greener vapor barrier?]; on top of 1x3; on top of T&G ceiling.

Q1: Zip seems like an unnecessary cost with EPDM acting as air/vapor-barrier right?

Could tape the plywood as cheaper belt and suspender air barrier over cheaper polyiso right?

Q2: since i don't NEED drywall (finished ceiling is T&G pine or Oak) - is there a better/cheaper/greener air barrier? (I really don't want humid SF air to get into joist bays!). Keeping in mind i need to screw the furring strips into the joists... so is drywall the best tightest air barrier after all considering furring strip-screws?

Bonus Q3: For Zip systems - why doesn't everyone use liquid Flash membrane rather than Tape. Seems way more foolproof / robust / easier to install etc. What am i missing?

Thanks so much!

John

Log in or become a member to post a comment.

Sign up Log in