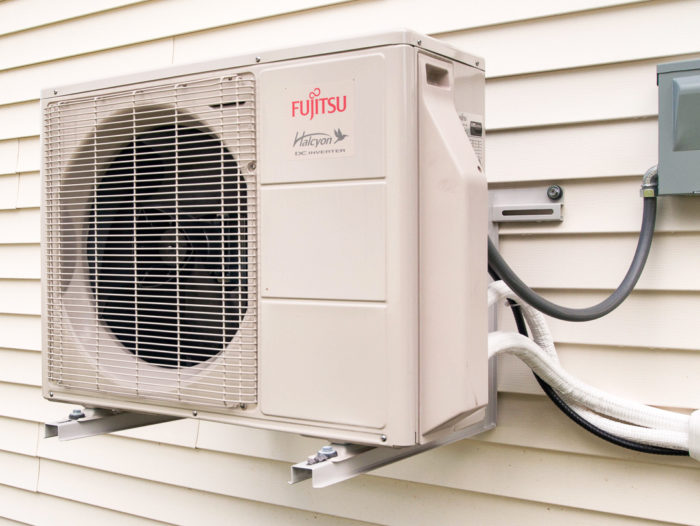

Image Credit: Scott Gibson

Ductless minisplit heat pumps have received a tremendous amount of attention in the last several years, and Peter L. would like to include one in his own house. There’s only one problem: an estimate that seems far higher than it should.

“I was quoted $4,800 to purchase and install a Mitsubishi Mr. Slim 1-ton unit (MSZFE12NA),” Peter writes at GBA’s Q&A forum. “That seems very high. Especially since it’s a new build and the 3-inch hole is already in the wall.”

Installers see minisplits as a niche market, Peter says, and because they’re not making money on the ductwork that a conventional heating and cooling system would require, they are charging “crazy install prices” to make up the difference.

In this case, Peter estimates that the installation should cost about $500, not the $2,000 his contractor has in mind.

That makes installing the system himself an attractive option.

“I might go the route of the DIY minisplit from Home Depot — Mr.Cool,” he says “I can get a 1-ton unit for $1,300 and install it myself since the refrigerant lines are pre-charged. The Mr. Cool unit (17 SEER) is not as efficient as the Mitsubishi (26 SEER) but at $1,300 for the 1-ton unit that cannot be beat. Even if it dumps out at 7 years of age, I got my money’s worth.”

Smart plan or not? That’s the topic for this Q&A Spotlight.

You’re paying for less risk

The question has come up before, GBA senior editor Martin Holladay points out, when Justin Fink, the editor of Fine Homebuilding magazine posted a question about installing a minisplit himself when he renovated his garage shop. That was back in 2013.

“If you pay for installation by a qualified contractor, you are paying for warranty service and…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

31 Comments

$4.8K is still too high

Just about 5 years ago a relative of mine in western WA had an FE18 installed by a Mitsubishi Diamond installer for less than that. That's a bigger and more expensive unit , and it was still a current model when installed, unlike the current quote for installing the now discontinued FE12, (It was not the newer and substantially more efficient FH12.) Even if it was the FH12, $4.8K would be on the high side for an installation in the PNW.

That said, in the past couple of years I've seen ridiculous proposals for inappropriate equipment at inflated for Mitsubishi equipment from Diamond installers in my area from sales-droids who seemed clueless about how to size them, as well as spot-on equipment selection at competitive pricing (also from Diamond installers.)

Even if the warranty is good for 12 years, it's not worth paying extra for out of date equipment of lower efficiency. Independently getting a handle on the load numbers and specifying the equipment yourself, then putting it out to competitive bidding seems to be the best strategy in my area, but it requires a fair amount of self-education (or input from competent people.)

YOU People are always ragging on HVAC contractors for not designing properly then you rag on HVAC contractors for charging too much. Good installers deserve to be paid well. Keeping sales staff abreast of the changes in the industry costs money. Doing the load call right takes time.

I see where y’all are coming from because this particular article was about a new build that had already been spec’d and the quote was for an out of date piece of equipment but seriously, install companies can charge whatever they want. If you don’t like it, then DIY is a fair option, or get another quote. It’s totally possible to build $3k of value into a minisplit install, but not every company will. Just because this particular guy didn’t see that does not mean that “4800 is still too high.”

If that quote came from a fly by night operation that makes their guys work with junk tools, gives them no benefits, and pays them like they’re flipping burgers then sure, in a sense, that price is “too high.” But if that quote came with a REAL load calc (with a damn blower door test), the installers are HVAC artisans equipped with the tools and skills they need to install a system that will run problem free (with regular maintenance)for 20 years then why take them over the coals for charging $4800? Nobody is making you buy that service.

Paul,

I agree with most of your points. See my Comment #9, below.

I see the headline...

"Most Ductless Installers Clueless, GBA Reports"

stepping over dollars to pick up pennies

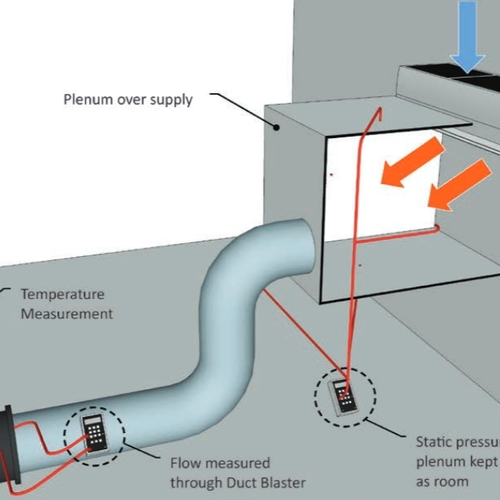

As Mark R says in the article, you cannot properly install a mini split heat pump without properly evacuating the line set to eliminate all air and all moisture from the line set. This requires a high quality vacuum pump and depending on the install and the time of year, the process can take between 2 and 4 hours when done properly (triple evacuation with dry nitrogen purge in between). If you skip this step, the system will kind of work initially, but efficiency will be low and you are likely to have premature component failure as the remaining moisture in the line set will contaminate the refrigerant and compressor oil.

For those interested in the effects of install quality (even among "professional" installers) I highly recommend the recent report "Ductless Mini split heat pump impact evaluation" authored by the Cadmus Group for MA and RI. On page 104 of that report, they include the interesting finding that a lower quality reduced COP by as much as 0.7-1.0 when compared to a proper install. So even leaving aside the likely shorter unit life, it is pretty clear that a 'cheap' install usually isn't 'cheap.

does cheap have to be incorrect?

Some of the implication seems to be that a self-install would simply omit evacuating the line set properly, but that's surely doing a disservice to people who are truly interested in learning how to do a job correctly. It seems that most people posting here are obsessive enough to fall into that category! Equipment such as an a/c vacuum pump isn't expensive enough to form much of a barrier; the hard part is collecting the necessary knowledge. HVAC has always seemed one of the most secretive trades (relatively little good DIY info out there), yet countless articles on this site demonstrate that some HVAC contractors really aren't providing the highest quality analysis to their customers (no offense intended to the many good contractors out there).

Scott

These spotlights are excellent. A really good distillation that allows the subject to come into focus.

Malcolm

Thanks. I'm glad they're useful.

Potential climate impact and the Chiltrix option

Part of the risk of any mini-split installation is the risk of an accidental release of refrigerant if the lines leak. Assuming people reading GBA are often motivated by reducing their climate impact, they should be concerned that a refrigerant release could undo a lot of other good work on minimizing climate impact. (R-410 has a global warming potential near 2000X higher than CO2.) It's possible that a meticulous DIYer could control that risk as well as, or even better than, a random professional, but for most people the best plan is probably to choose a highly qualified professional.

For DIY, I think that a Chiltrix air-to-water heat pump is a better option. Yes, there's a lot to learn to design and install a hydronic system that works well, especially when it's for cooling as well as heating. But the Chiltrix system includes a variable-speed pump and controls inside the unit. And what i think is the key advantage: the refrigerant connections are all factory made inside the unit. The lack of refrigerant lines outside the unit reduces the chances of leaks, and reduces the quantity of refrigerant needed, so there's less impact even if it does at some point leak due to some other failure. Most DIYers would do best to hire a mechanical engineer to design the system if they go with Chiltrix, but I think they could install it themselves.

HVAC installer or heart surgeon?

In L.A., to replace an 18,000 BTU with a new Mitsubishi (so the 220 v & hole in wall were already present) required calling 27 HVAC contractors to receive four bids. Most wanted to send out a "Comfort Specialist" in 2 or 3 weeks, despite my assertion that I already had experienced what I wanted—I just needed a replacement.

Two bids came in at $3500; one at $5,000; and one at $8,000! Unit cost was less than $1800, and my electrician made the electrical connection. The installer with one helper earned $1700 for the five hours. He probably paid his helper $20/hr, leaving over $300/hr. for himself.

The $8,000 bid would have netted $1240/hr to be split with the help. It would be cheaper to hire a heart surgeon to do the job.

In other countries, mini splits are just a commodity.

Response to David McNeely

David,

I'd like to make a few points:

1. I worked as a roofer and builder for a couple of decades. Work in the trades is honest work, and there is a shortage of skilled workers. All GBA readers should be urging their daughters and sons to enter the construction trades.

2. I never netted anything close to $300 an hour on any job (or even $30 an hour, for that matter). I worked without health insurance, paid vacations, or any type of retirement plan. I wasn't very smart about business.

3. Some electricians, plumbers, and HVAC contractors make a very decent living. Stop whining about it. Get training and open an HVAC business. We need more skilled workers in the field.

-- Martin Holladay

A burdened cost of $20/hr is unlikely (@ David McNeely)

Unless he is exploiting undocumented immigrant labor there's no way a contractor would have cost structure anywhere near as low as $20/hour for unskilled/semi-skilled labor after paying the various required insurance (including unemployment insurance, workman's comp, etc). The net pay to the employee might be that low, but with the overall picture including the overhead of keeping the lights & phone on at the office is probably starting at $50/hr at the low end, and is more likely to be closer t$100/hr end for a semi-skilled already trained helper, to ~$150/hr for a trained & certified tech. (If the company offers a health insurance package to employees it can be even higher.)

The estimate for the cost of a heart surgeon is also unrealistically low.

$3500 for swapping out a 1.5 tonner where some or most of the ancillary stuff was already pre-installed is realistic, and not a gouge, whereas the $8K bid sounds like someone fishing for enough margin to keep up with the fees at the marina where they keep the yacht.

Mr Cool Tradeoff

To all of the people suggesting that it's impossible or high risk to DIY a minisplit install, how do you think that the "DIY" models are attempting to get around this? Do they simply accept that there's a potential hit to the COP due to the uncertainty of the pre-charged lineset? I also wonder what the real world performance difference is between one of these units and one of the top end Mitsubishi's. You can buy a fair amount of electricity for the ~$3k cost difference between a user installed unit and a professionally installed Mitsubishi, Fujitsu, etc.

@Dana Labor Rates

Here in the great state of NY, home of some of the highest insurance rates in the country, to employ a person in the designated insurance field of "construction" including workers comp, unemployment, liability etc.I pay an about an additional 46% on top of flat wage.

So an entry level laborer at $16/hr would cost about $24/hr, no health insurance.

If your are a small business and your other costs to run your business are pushing your actual costs to employ that laborer to $50/hr, good luck I don't think your are going to be in business too long

@David. Just an fyi. California is one of the most

expensive states in which to employ people. For example they pay OT per the day (8+ hrs) not per the week (40+ hrs). Very few states do this.

What, no overhead? (@ Kye Ford)

What no accounting burdening of the hourly costs with distribution the office or capital expenses in the NY analysis? Counting only the marginal cost is disingenuous. It's not merely the associated insurance etc adding up to 46% for the individual employee. An HVAC business without an office, licenses, tools, or a truck won't be in business for very long either. If you can get all that for $24/hr in a full accounting it's quite a bargain!

In my small 6-person (not construction) business there are a couple people currently working at less than $16/hr, but when the full costs of the business it broken out by the hour it's still ~$50/hr, even after the health care benefits are separated out, and it's not because of a gold-plated office.

It's unlikely that a typical mini-split crew in my area would have unskilled $16/hr labor as the "...one helper...", but maybe that happens in CA(?).

A better comparison

The point of comparison should be through-the-wall units. I can buy a new 12+ EER window AC for under $200 and install it myself; it plugs right into a standard receptacle. A window unit with heat pump functionality is $400 and a PTHP is $700. Especially in cooling-dominated climates (i.e. at least half the USA and most of the developing world), this is the competition. We're talking commodity vs custom here. To compete with a commodity, custom work has to be substantially better (check), and the price still has to be *reasonable* (nope). 5-20 times the commodity price is not reasonable.

I live in a solidly middle-class neighborhood full of families and retirees. Tellingly, there zero houses with mini-split compressors. However, a number of houses have window AC units or PTACs permanently mounted in wall sleeves. One such house in my neighborhood has a 7 kW solar array on the roof. Evidently the economics favored more PV and less efficient equipment. Once the sleeves are installed, homeowners can replace the equipment themselves forever. Also these devices come in smaller BTU sizes than mini-splits, making them better suited for per-room use anyway, especially for bedrooms. Finally, cheaper mini-splits are now no more expensive than PTHPs (example: pioneer WS009AMFI22HLD), so it's eminently possible that their tech will eventually make it into the commodity machines that are DIY-installable. Through-wall units can also include ventilation, and it's only a matter of time before someone puts a small HRV in one. The game may soon be up for the expensive boutique mini-splits if installers don't figure out a way to cut their prices dramatically. You don't see a lot of refrigerator repairmen anymore...

The FE12NA is a heat pump, not just an air conditioner (@ NateG)

The FE12NA quote that prompted this blog piece is a 1-ton cold climate heat pump with specified output down to -13F, and keeps running at temps down to at least -18F (below that it may turn itself off to self-protect due to the temperature sensing thermistor being out of range, according to some of the info sheets.) It has enough output to be the primary heating source for modestly sized better than code houses.

Most people in cooling dominated climates wouldn't be installing one of those, anyway (and certainly not for $4800!) Five years ago on a deep energy retrofit I was involved with quotes for FE18 1.5 ton Hyper Heating cold climate minisplits were in the ~$4500 range, all-in for a new installation, and that's what they were going for in markets the other side of the country too. (I have multiple friends and relatives heating their homes primarily with the FE18). A simple swap-out of a 1.5 tonner shouldn't be more than $3500, but I'd be surprised to find somebody who would do it for much less than $3000, especially in higher priced markets (such as L.A.?).

Sure in temperate or cooling dominated climates the $500-$1000 third-world DIY mini-splits can work, but a wall-plugged unit wouldn't meet code as the primary heat source for the room (or whole house) the way a hard wired technician installed & commissioned mini-split can, and it's unlikely to have the same robustness as the first-tier cold climate mini-splits. They're not really apples-to-apples comparable.

I'm not holding my breath waiting on the model release of PTHPs or PTACs outfitted with HRV core ventilation. The noise levels of PTAC/PTHP still leave something to be desired, but they've gotten better once scroll compressors arrived on the scene. As for sizing, I've never seen a PTAC that can run down to the 1000-2000 BTU/hr range, but there are several 3/4 ton mini-splits (and at least one half-tonner) that can.

PTAC etc.

Really good point, Nate. A lot of the advantages of mini-splits over various alternatives are that all the best variable speed high efficiency compressors and fans are used, rather than that the capabilities of the mini-split are inherently better. The one place the mini-split really inherently wins vs. something that is mounted through the wall is on noise. You can do better in a through-wall unit with variable speed, but there's only so low you can go without separating the compressor--either by using mini-splits, or with air-to-water systems.

Quieter PTHPs are the future

Dana, you said, "wall-plugged unit wouldn't meet code as the primary heat source for the room (or whole house) the way a hard wired technician installed & commissioned mini-split can"

I've been installing whole house PTHPs and have had no trouble with code officials.

Cost to furnish and install minisplits

While it is appealing to the uknowing to assume $300 - $500 ought to suffice to get a $1500 wholesale minisplit heat pump installed, reality suggests otherwise:

In addition to the usual issues of employee pay, benefits, training, vehicles, insurance, licensure, office and shop space that confront any tradesman, Furnishing and installing aminisplit or any other HVAC system requires:

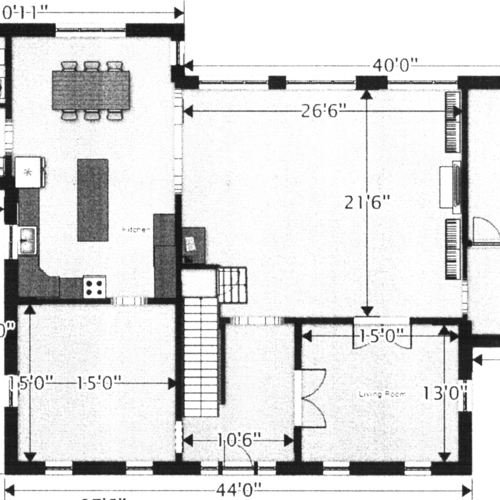

1) before anything else, someone needs to run a load calc - that means sending a competent person to site (in a vehicle) with a laptop or tablet loaded with licensed software. That guy needs to know how to do a Man J, and it will take some time to make all the necessary measurements and ask the right questions of th cleint.

2) Generally we'll propose 2 - 3 system options from which the client chooses what best fits needs - proposal generation takes time and money.

3) Once the system is selected, a mechanical permit is needed.The city or county will require a permit - that includes a fee, administrative activity to pull the permit, and more to schedule the inspection, requiring coordination with the homeowner.

4) Back office activities include getting the system on order, taking delivery, and then getting it and all its accessories and supplies acquired and staged for pickup by the install team.

5) In addition to the much-aforementioned evacuation, consider also nitrogen purge, brazing or flaring of copper connections, and pressure testing. There is the cost of the copper lineset, and its insulation. Minisplits also need a specialized power and data cable between indoor and outdoor sections.

5a) Complete and proper evacuation should be verified with a micron gauge, competently used.

6) Minisplits, like any other HVAC system, generate condensate which must be reliably collected and drained so as to meet code and not create a nuisance. The condensate drain pipe must be carefully sloped and insulated, possibly even pumped. The indoor unit, if in a sensitive location, may need an additional condensate overflow interlock to prevent damage.

7) The outdoor unit needs to be securely fastened (hurricane code) to a suitably selected, sized, and elevated mounting pad.

8) The client will probably want assurance that the installer has experience and credentials to improve probability of an efficient reliable system - EPA certification is a bare minimum, NATE and / or manufacturer certifications highly desirable.

9) The client will likely need a bit of hand-holding as the system is placed in service - a hands on tour of the control / thermostat, a discussion of maintenance requirements as well as warranty registration of the newly installed system.

10) In addition to the usual during-business-hours back office infrastructure normally taken for granted, most clients value the ability to contact their HVAC contractor after hours, the other 128 hours of the week not covered during 9 - 5, Monday through Friday. Emergency service requires an on-call technician ready to respond as well as availability of loaner portable or window air conditioners and space heaters.

11) After all of the above is furnished and paid for, there is the question of what is a reasonable profit margin for the contractor? A mere 10% profit margin, after all is said and done would please most contractors. Is that too much to ask?

Well said!

Response to Curt Kinder

Curt,

Thanks very much for taking the time to post your helpful comments.

-- Martin Holladay

Amazon offers installation

I have no experience with it but Amazon sells minisplits with installation. Looking at a few models, the installation extra charge is about $950-$1200. As an example, a Cooper and Hunter 27 Seer 9000btu unit is $1258 and installation is $977.49. Installation includes:

Installing one customer-supplied mini-split system to customer's preferred location

Connecting outdoor condenser to existing power supply

Connecting indoor unit to existing power supply

Connecting the outdoor unit to the indoor unit

Unit test and job area cleanup

Larger or more complex projects may result in an updated price estimate from providers

Hydronic alternatives?

Charlie Sullivan, thank you for mentioning refrigerants and the danger of releasing them and counteracting a lifetime of CO2 reductions...

The next step is to look beyond HFC refrigerants, since I assume that all refrigerants created will leak out someday. In fact, when I read that HFC is 1000 to 9000 times as potent as CO2, and I see all the air conditioners and other cooling devices around, I wonder if all this CO2 reduction is for naught...

Anyhow, I am looking to heat two living units (house and apartment) in a yet-to-be-built home, which have been modeled (using PHPP) to have total heating loads of 11k BTU and 6.5k BTU respectively.

Due to concerns about refrigerants, I am contemplating a Sanden (CO2) Hot Water Heat pump tied to a baseboard water radiant system... but I'm thinking at these low loads, especially if I have wood stove supplemental, that I might be better off just installing baseboard (radiant) electric and calling it a day. (There is no cooling demand shown in the model).

Maybe the answer is to reduce cooling loads to zero and then eliminate refrigerants. Do you have any thoughts regarding the comparative system and installation costs of hydronic baseboard hot water (tied to domestic Sanded CO2 hot water tank) and a baseboard electric hot water system (assuming the Sanden hot water tank is still used for DHW)?

My hunch is that the electric baseboards will be less expensive to install, somewhat more expensive to operate, but potentially less expensive long term due to inherent ability to have separate zones in each room, and very low long term maintenance costs.

Reducing cooling loads to zero? In zone 5A?

...in a PHPP modeled house designed for making the most of solar gain? Zero cooling load in zone 5A is not possible, except maybe in a cave, but even in a solar-tempered low energy cave dwelling there would be some cooling load.

Don't over-think the refrigerant thing.

Or maybe you SHOULD overthink the refrigerant then?! Let's go there, shall we? (Lessee, get out crayon & napkin, plant butt firmly in armchair... ready... set....)

Yes, HFC410A is a very potent greenhouse gas ( 100 year GWP of ~1725x CO2) that will eventually leak, but the leakage rates overall are pretty small, as are the refrigerant volumes in a mini-split, typically about 3lbs of R410A per ton, plus another pound for system with "reasonable" refrigerant line lengths call it 4lbs. Assume the fleet average leakage of all mini-splits is on the order of 5% per year (probably higher than reality for US installed mini-splits, might be low for third-world pre-charged systems), over a 20 year lifecycle the mini-split fleet average might leak the whole 4lbs, but it's spread out over 20 years. With a 100 year GWP of 1725x CO2 and a leakage rate of 5% per year (probably higher than reality for the fleet of heat pump systems in the US) that becomes 4lbs x 1725 x 0.05= 345 lbs of CO2-equivalent per year...

...or a bit less than 1-lb of CO2-equivalent emission per DAY.

OK, emissions are emissions, and we all want them to be lower, right? However...

Driving a 50 mpg Prius (a lower-than-US average) 25 miles per day burns a half-gallon of fuel, releasing about 10 lbs of CO2. That's just the tailpipe CO2 emissions, not including emissions from drilling, pumping, shipping, and refining the fuel. That planet destroying Prius is puking up a full order of magnitude more climate damage than mini-split leakage. To match the damage of even a low-annual miles Prius they would have to leak an average of 50% of the refrigerant every year.

In the near term, where is the emissions-lowering budget (mental effort &/or financial) is better spent? For most people it's better spent on reducing transportation energy emissions, or their FOOD choices: https://link.springer.com/content/pdf/10.1007%2Fs10584-014-1169-1.pdf

That's not to say we can be sloppy in how we use R410A in heat pumps, only that it's small-potato stuff in the bigger scheme. In the intermediate and longer term R410A and other climate damaging refrigerants are going away. In 20-30 years when it's time to replace the mini-split, the heat pump that replaces it will be using something more benign, CO2, or HFO1234yf or HFO1234ze, all of which are being used in some refrigeration systems today. But there are MUCH bigger greenhouse gas problems to be focusing our efforts on in the mean time.

Hi Dana -

I am not sure if this is the right place but I wonder if we could chat off-line? I'd like to discuss a project with you. You can contact me at [email protected]

Thanks,

Jonathan Scholl

Hell, minisplits not worth it considering the hyped benefits in comparison to the prototype central air system.

Industry always finds a way to nullify the cost savings of bucking the traditional(central air) ways if doing things.

I am a little late to the party on this article, but I have some information to add.

I have a Mitsubishi 9000 BTU minisplit in my passive house, and it developed a leak in the indoor coil after less than a year of use. The part was sent to me under warranty, but the cost of installing it was substantially more than the entire head. I was involved with the replacement. It took me and my HVAC guy 6 hours to do the job.

So, I would say to those worried about invalidating their warranty by installing the system themselves, go for it. You might want to pay a simple service fee to have a technician come out to do the final evacuation and commissioning of the system, though.

The reason that it took so long to replace the coil is that everything in the unit had to be removed to get access to the coil. Plus there was the PITA aspect of getting the unit off the wall - a two person job.

I don't know, the many DIY alternatives make using a pro to do this work very dubious. Sure, you have to take your time. But it's absolutely not rocket science. The Mr. Cool and Pioneer models that come with pre-loaded refrigerant are not difficult to install at all, if you follow the directions (I installed both in our house last summer ... not sure if they are the only brands where the linesets come pre-loaded). They work just fine, are quiet, and come with good warranties.

It's incredibly annoying to scan some of the HVAC pro forums where they look down on home installs. Let's break it down:

- Head unit/ air handler: there's absolutely nothing to installing the head unit, as long as it's level and properly attached to studs. No opportunity for a pro to magically "add value" at this step.

- Electrics: it's dead easy to install a quick-disconnect, either 230v or 115, on the outside wall. But if it gives you the heebie-jeebies to do it, an electrician can do it without too much expense. No opportunity for a pro to magically "add value" at this step.

- Condenser: mount a bracket on your wall or use a ground pad. Needs to be screwed into studs or good structure if using the former; needs to be level if using the latter. No opportunity for a pro to magically "add value" at this step.

- Connecting linesets and adding refrigerant: this is the only step that a pro can possibly add value on. That being said, the DIY units are nearly foolproof, as long as you can live with a pre-cut length. The procedure by which the linesets are attached is pretty bombproof excepting for the fact that most homeowners aren't likely to have an open-ended torque wrench, so there's a little bit of guesstimating called for there. The procedure by which refrigerant is added is, in theory, something a pro could do better than a DIY-er, but the process these manufacturers have perfect is mighty foolproof. Assuming the lineset has been attached with zero leaks, it's very hard to see how Joe Homeowner, allen key in hand, could screw this up.

With these steps having been done correctly, you're going to have a really tough time convincing me that a pro installation would be better in any way. Heck, Pioneer now sells DIY units that are in the low 20's, SEER-wise. If you are even somewhat experienced in DIY and are willing to take your time and work with a little bit of care, there's absolutely no reason why you need a pro to install a minisplit.

FYI, current installation rates for the Boston area after 5 bids from reputable companies is $6k-8k per head (4 ductless heads, FS06x 2, FS09, KJ18). I wish it was still only $4800 for this type of install.

Log in or become a member to post a comment.

Sign up Log in