Image Credit: Zero Energy Project

This is the second of two articles about heat-recovery and energy-recovery ventilators based on training developed by Bruce Manclark and Dan Wildenhaus of CLEAResult. Part 1, which covers equipment selection, is available here. This post originally appeared at the Zero Energy Project.

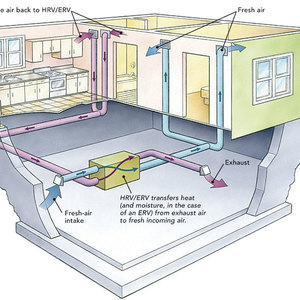

Heat-recovery ventilators (HRVs) have been used in homes and commercial buildings for many decades, mostly in colder climates. They provide fresh air and distribute it throughout the building. Most experts would agree that it’s best for an HRV to have ductwork that is properly sized and located for its own use. A dedicated ventilation duct system generally offers the best efficiency, health, and comfort.

However, most homes in North America use a forced-air heating and cooling system that also has an elaborate system of ductwork to move conditioned air to all the rooms. It makes sense to use these same ducts to distribute fresh air. Integrating the HRV with the forced-air system reduces the amount of dedicated ductwork needed, which slashes material and installation costs. Plus, fresh air is more quickly and evenly distributed throughout the home. In the past, some integrated systems have achieved limited success due to installation issues.

According to Manclark, integrated systems can work well if properly planned and installed. The key is a smooth connection between the two duct systems and proper controls.

Manclark offers these five Golden Rules for HRV integration:

While some of these rules are self explanatory, we’ll elaborate further on a couple of them below.

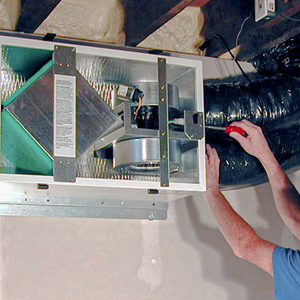

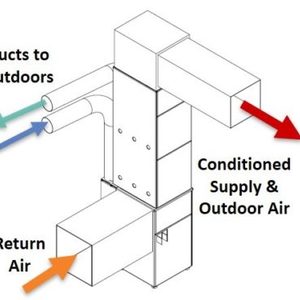

Always use the injection port design

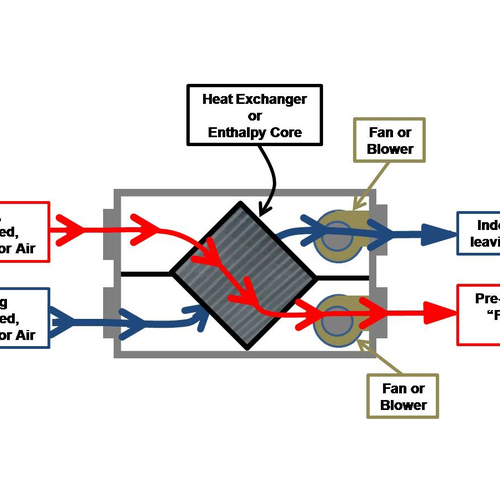

This is Manclark’s big innovation. The large blower in the air handler is six to ten times more powerful than the much smaller fans in the HRV, so it’s critical to create a smooth convergence where the air streams meet. Manclark suggests attaching the HRV duct, which is usually 6 inches in diameter, to the air handler’s supply trunk using a 90° elbow pointed downstream. Airflow inside the supply trunk surrounds the elbow supporting the weaker HRV stream rather than fighting it.

In the past, some installers have shown a preference for inserting the HRV supply into the air handler return trunk. The idea is that negative pressure — or suction — in the return pulls air through the HRV. Manclark takes the position that this arrangement creates large pressure imbalances and leads to overventilation.

Buy an electrically commutated air-handler motor

You have to move a lot of air to carry heat, much more air than is required to simply provide fresh air. “The large blower in most air handlers can move up to 1,500 cubic feet per minute and generate a considerable amount of air pressure within the ducts,” said Wildenhaus. “The typical motor driving an air handler’s blower requires a lot of power, up to 650 watts.” In contrast, HRV fans are much smaller, generally rated for 100 to 300 cfm and draw 150 to 400 watts. Using a large air handler blower with a single set speed to move a small amount of fresh air makes no sense.

An electrically commutated motor (ECM) in the air handler solves this problem. It is inherently more energy-efficient, and more important, it can be controlled to run at many different speeds. At the lowest setting, a 16-pin ECM would typically draw only 40 watts. “This is not the ECM called an X-13,” cautions Wildenhaus. “To gain this level of efficiency, be sure to get the 16-pin ECM.” While an ECM is a great efficiency upgrade for any air handler, it’s an absolute necessity when using a forced air system to distribute ventilation air.

Three control options

In addition to Manclark’s five Golden Rules for HRV integration, the controls of both systems need to cooperate. Manclark offers three options.

Option 1: Configure the HRV and air handler to both run continuously while a smart controller boosts the flow of the air handler fan when heating or cooling is needed. At the lowest speed it can move enough air for sufficient ventilation while consuming as little as 40 watts. This is far lower than a typical single-speed furnace blower that can consume as much as 650 watts. This option distributes fresh air while reducing the energy use and noise of the air handler. It also allows fresh air, which is generally colder, to mix with house air for a more comfortable temperature.

Option 2: Choose an HRV that has dampers that open only when ventilation is called for, or add them in the field. The air handler can operate normally, because the dampers control the flow of fresh air from the HRV. This prevents air from flowing in reverse through the HRV when the air handler is on, but the HRV isn’t. The HRV controller operates the air handler’s blower when ventilation is engaged. Some HRVs come with backdraft dampers built in.

Option 3: Interlock the HRV controls with the air handler blower so that the air handler cannot run without the HRV. The controls must be set properly to operate both systems so that the HRV runs during calls for heating or cooling, as well as calls for the air handler to run whenever the system calls for ventilation. This option maximizes distribution with every call for ventilation, while ensuring that all heating and cooling runs integrate ventilation.

In this case it’s best to choose an HRV sized properly for the basic whole-house ventilation required — nothing more. In other words, don’t oversize the HRV so it can be boosted to high speed to clear bathrooms quickly. Use a smaller HRV along with spot ventilation fans in bathrooms. As with all ducted systems, it’s crucial to run the ducts inside the building’s conditioned space.

Installation check

Once the system is installed, it must be double-checked for proper operation. Measure and record these parameters:

- Airflow of both streams with the air handler blower running at low speed.

- Opening and closing of dampers.

- Amp draw of air handler fan on low speed.

- Room by room airflows.

- Condensate pipe routing.

Then, be sure to place a copy of this record in the owner’s manual. It’s a good idea to label the ducts, wires, and controls for future reference as well.

Ducts inside conditioned space

The air flowing through ductwork, whether it’s the ventilation or heating and cooling system, is really indoor air. So, the ducts should be located inside the conditioned envelope of the home. Unfortunately, standard construction practice almost always runs ducting through unconditioned spaces such as attics and crawl spaces. This causes unnecessary heat loss that can reduce overall system efficiency by as much as 20%.

When heating and cooling ducts carry the extra flow of ventilation, longer operating time makes the problem even worse. There are many methods for designing homes with ducts inside the conditioned space. (In existing homes with ducts outside the conditioned space it is important to thoroughly seal the ducts and wrap them with insulation.)

Good indoor air quality is essential for all homes whether or not they have air handlers. HRVs and ERVs are the gold standard of effective, efficient ventilation. But achieving the full benefits of HRVs requires careful equipment selection and installation for specific ducting systems. For more details, see the HRV System Best Practices Poster at BetterBuiltNW.com.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

12 Comments

I understand the cost impediments to having seperate ducts

but this solution appears to be very complicated with regards to execution. I can see why homeowners don't both with maintaining these systems once the dampers go.

Also, how does the 90 degree bend into the supply trunk slow down the speed of the outside air moving through the HRV when the air handler is in cooling/heating mode?

Pull exhaust air from the bathrooms

The article doesn't elaborate on this and it should because it's an important point. I take it to 'mean pull exhaust air from bathrooms and nowhere else'. T

The general practice is to draw ~60 cfm from the kitchen and 20 cfm from the laundry room. In most cases, the capacity of the HRV is around 120 cfm at high speed, this leaves little capacity to draw much more than 20 cfm from the bathrooms. 20 cfm is not enough to keep the mirrors clear and get the poop smell out in a reasonable amount of time. So, builders usually put exhaust fans in the bathroom or let the occupants wallow in the stench.

Unless the occupants are hanging laundry in the laundry room, not much humidity is generated in the laundry room. If they do, draw ~20 cfm from there.

The big issue, though, is the 60 cfm from the kitchen. If you burn supper, a 60 cfm draw several feet away from the stove is not going to get the smoke out, you need a range hood vented outside. So, the requirement for kitchen ventilation is best satisfied with a range hood.

This approach allows you to draw 70 or 80 cfm from the bathrooms and eliminate the bathroom fans.

Response to David Baerg

David,

The traditional advice from HRV manufacturers was to pull stale air from bathrooms and the laundry room -- rarely from the kitchen, which most HRV manufacturers assume is vented with a range hood exhaust fan.

In my 2010 article, HRV or ERV?, I wrote, "In most installations, the fresh air is delivered to the living room and bedrooms, while the stale air is removed from bathrooms, laundry rooms, and sometimes the kitchen."

For more information on this issue, see Does a Home with an HRV Also Need Bath Fans?

Response to David Baerg (Comment #3)

David,

Q. "The article mentions that it prevents overventilating. Is there really such a thing?"

A. Yes. Overventilation comes with an energy penalty, and using more energy than necessary contributes to global climate change. Moreover, the energy penalty hurts homeowners in their pocketbook.

Overventilation during the winter can cause the indoor air to be irritatingly dry.

Finally, overventilation during the summer introduces large moisture loads into the house. The extra moisture can cause problems (including mold) and increases the dehumidification load carried by the air conditioner.

Supplying fresh air to supply trunk

As a designer I'm curious about this. My first concern is that manufacturers' usually instruct the installer, when installing a partially dedicated system, to run the supply from the HRV to the return. I don't imagine that running it to the supply trunk or plenum is going to do any harm. But will it void warranties?

Secondly, I'm wondering about what advantages there are to this approach. The article mentions that it prevents overventilating. Is there really such a thing? The only people getting enough fresh air are those who live outdoors. And, if overventilating is a concern, how much does having the supply from the HRV connected to the return trunk increase ventilation?

Responses to Martin Holladay

Hi Martin,

Where I am (Ontario), the common method since the 1980s has been to have an HRV exhaust in the kitchen. I get push back from some mechanical contractors, and in one case, from municipal inspectors, when I design systems without an exhaust in the kitchen. I'm happy to hear that isn't the case everywhere.

On your second point. I was being a bit flippant with that comment. I agree that we don't want to overventilate. I'm questioning how many houses really are being overventilated and, for those that are, is it caused by connecting the HRV supply to the return air trunk? My guess is that it's more likely bad design, or the occupants running the system at a higher speed than necessary.

But Manclark and Wildenhaus have looked into it more than I have. I would like them to elaborate on this point.

> Airflow of both streams

> Airflow of both streams with the air handler blower running at low speed.

Why is it not important to also check when the air handler is blowing at higher speeds? Furnace supply pressure might completely stop airflow from the HRV.

Let's see some figures on how well such a design maintains balance and avoids under-ventilating - with various flow rates and pressures (HRV and furnace).

Over Ventilating

I'm also in Ontario, living in a custom built 2400 sq.ft., 2 storey + basement home (1998, high quality but not super-insulated). State of the art (in 1998) LifeBreath HRV 200 and Carrier Infinity furnace with humidifier etc., and well ducted hybrid system. LifeBreath has its own exhaust runs from all bathrooms and the laundry room.

I can tell you with the LifeBreath set to LOW (approx. 30% of max. cfm I believe) all the time, and the furnace fan set to continuous ON (hybrid system), it definitely over ventilates. Obviously no CO2 or VOC monitors in that era, so I can't be sure that it's "over ventilating" from that perspective, but from a comfort and energy perspective it is clearly over ventilated. Middle of winter the flow through humidifier can't keep up either, even when set to only 30% RH. Getting ready to build another house so not too concerned about retrofitting this HVAC.

It's clear to me that 20 years ago they just took a pot shot at trying to ventilate "tight" houses, and after a fair amount of recent reading it appears to me the entire ventilation issue is still a big unknown. Very little solid data, poor control systems, and little to no design guidelines or proper standards. Everyone's flying by the seat of their pants. The manufacturers of the HVAC equipment are in the dark ages, and the ASHRAE standard isn't far behind. It's appalling.

Are there any new residential builds anywhere where they can control and measure ventilation based on live measurements of CO2, VOC's, and humidity levels - room by room - without blowing away (pun intended) all of the energy savings from building a tight house?

Dettson 3 Wire Modulating Furnace integration with Air Exchange

Could I convince anyone who is interested, to please write about the interconnecting of a well-modulated furnace that is *designed to be connected* to devices such as HRVs?

I understand the Dettson Supreme modulates down to zero and has two or three wires for interconnectivity . . . perhaps there are other models?

This type of integration will definitively operate the ventilation system whenever called upon - even in the absence of any heating or cooling activity . . . doesn't this present a newly-acceptable way to actually embrace integrating ventilation with HVAC ductwork?

Particularly, doesn't the low, more consistant cfm delivery inherent with Dettson 'Smart Ducts' also contribute to the viability of integration?

Remodels are paving the way with necessary integration, but they have many constraints to overcome, which makes it difficult for new construction designs to emulate the integrations. I contend that integration of HVAC with air exchange is just as attractive to new construction as it is necessary for remodels . . . Help? Any conclusions?

Bruce, Martin and friends: I am a Massachusetts HERS Rater, often called on by clients to advise on the design of a ventilation system and always called on to verify the function and flow. What are your thoughts on a HRV that discharges into the supply plenum as you suggest, but is not interconnected to the air handler's blower?

Mass code requires the HRV to run constantly, but not the blower. In our homes, of course, the air handler is often idle because the loads are so low. It would seem wasteful to me to run the blower 24/7 at any speed when there is no load. In addition the HERS model will have to identify and include the blower's power load, which could cause the house to fall short of code.

What is the downside of simply introducing the modest 100 cfm or so of the HRV into an otherwise calm supply system?

ECM motors and Interconnecting the controls introduce cost and complexity that many spec builders would want to avoid. Not to mention the likelihood that the HVAC and Electrician will get it wrong and onto the HERS Rater will fall the responsibility for testing troubleshooting and remediation...

Kevin,

Here is a link to an article that describes a couple of different ways to hook up an HRV to the ductwork of a forced-air heating system: "Ducting HRVs and ERVs."

I don't like this approach, because these systems are hard to commission. The downside of the approach you suggest -- which is somewhat different from the approaches described in my article -- is similar to the downside of the approach I call the "exhaust ducted" approach. Here's what I wrote:

"With an exhaust-ducted system, an electrical interlock between the HRV/ERV fans and the furnace fan is an option. With an interlock, the system suffers from the same energy-penalty problem as a simplified system. If the fans aren’t interlocked, the ventilation system uses less energy. When the furnace is operating, fresh ventilation air is distributed through the HVAC system’s supply ducts. ...

"The exhaust-and supply-air flows of HRVs and ERVs need to be balanced after they are installed. This balancing process is known as commissioning. Exhaust-ducted systems without interlock wiring between the HRV/ERV and the furnace fan are particularly hard to balance because there are two different fan conditions: when the furnace fan is operating and when it isn’t. Any attempt to balance the system with dampers will only be accurate in one of these two conditions, which is another reason why fully ducted systems make the most sense."

Mr. Sullivan, great article and point about the ECM.

Gentlemen/Mr. Sullivan, I'm trying to determine whether my new Trane S9V2 gas heater has the 16 pin ECM or the 'X-13' ECM Mr. Sullivan mentions above. I can't find this info on any of Trane's spec sheets. Can anyone tell me where I can find this info? My installer doesn't seem to have a clue, and has probably never been to greenbuildingadvisor.com or any other site to expand his HVAC knowledge as all he cares about is giving the lowest bid to win the job.

Thanks!

Log in or create an account to post a comment.

Sign up Log in