Image Credit: ConSol

Image Credit: ConSol Image Credit: Building America

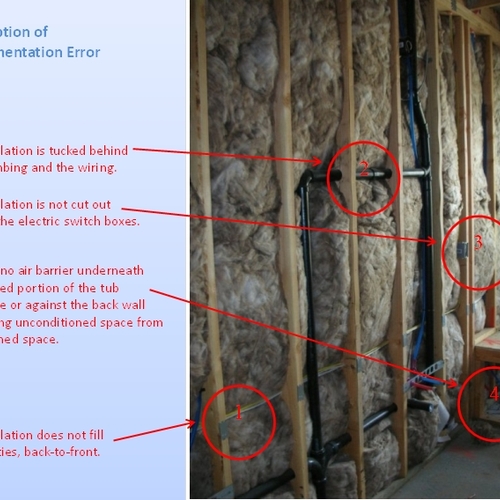

In many areas of the country, homes are receiving Energy Star labels they don’t deserve. Major errors like the ones shown in this photo are supposed to be caught by the HERS rater who performs third-party verification services. This home slipped through the cracks.

The photo shows at least four errors serious enough to have prevented the home from receiving an Energy Star label. Can you spot them?

Next week, we will post the answers that a Building America team, BIRA, came up with.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

12 Comments

insulation grade

if it is an interior wall and the insulation is for sound-dampening, then the only thing I notice is the lack of air-abarrier on window wall; if it is an exterior wall and insulation is for thermal value, then compression, not fitted around wires & pipes, not on plane with stud face, no air-barrier at tub, small pieces added at bottom, cavity void of insulation, no insulation at rim.

At least PEX is freeze tolerant

The bathtub hot & cold supply lines have both wandered to the cold side of the insulation on this exterior wall. Yikes!

WOW! Who did this?

1- Insulation not scored around pipes and wires so insulation is compressed

2- No house wrap/air barrier behind tub

3- no air sealing ,top plates/bottom plates/window frame/jack studs not caulked

4- Studs that are close together appear to not be insulated

5-Looks like below the tub did not get insulated

6- Insulation around pipes appears to have large gaps

Hey at least they managed to foam the plumbing through the top plates....

How bad must it get?

Any builder paying an "insulation contractor" for this type of workmanship has to be turning out some very shoddy projects. Quality builders of the world unite and expose these fraudsters for what they are.

Sound batts?

Is there any chance this is not actually an exterior wall, but a partition wall insulated with "sound batts?"

I hope so....

I hope that's just (poorly

I hope that's just (poorly installed) sound abatement too.

Running the plumbing through an exterior wall would bad enough, even without the batts that are thinner than the cavity with all the compressions & voids behind electrical & plumbing, no interior air-barrier, and no air-sealing on the penetrations between stud bays (at least they foamed the penetrations through the top plates.) It looks like the batts were too short for the stud height too, with a short section cut and wadded into the bottom to make up the difference. If this wall performed to even 2/3 the labeled R of the batts I'd be surprised.

But sad to say, I've seen worse. :-(

Looks like those are roof

Looks like those are roof trusses terminating at the wall plate, so almost certainly an exterior wall. Blocking between the trusses looks to go right to the decking, so no vent space? And why bother with 2 x 6 wall framing when you don't fill 'em, and why no energy heel on the trusses?

What’s Wrong With This Insulation Job?

Besides the above comments, the insulation should have been split around the wires and pipes, not just compressed to fit behind. There are nailing plates missing over drain lines and vents. If the water pipes are going to be in an exterior wall,(not prefered) they should be on the inside or heated side of the insulation and covered with something to protect them from nails.

It looks like they have tried to get away with using used (and very dirty) insulation that was meant for a 2X4 wall on a 2X6 wall, so it is not deep enough. It is not tight to the sides or bottom or top, and there is no vapor barrier.

More background info on the photo

I've read Rob Hammon's "answer" which will be published next week, so I know a few facts that weren't clarified in this introduction.

Thanks to everyone who has commented -- great observations. Here are a few additional facts:

1. This is an exterior wall with thermal insulation, not sound attenuation batts.

2. The color of the batts does not indicate that they are recycled batts; some fiberglass batt manufacturers are reducing the use of dyes and selling batts with more "natural" colors to aim for the green market. (Don't ask.) That's what they look like when they are new.

Keep posting those comments!

Optimum Value Engineering (OVE)

In addition to the comments above, ENERGY STAR requires that studs in 2x6 walls be on 2 foot centers unless the load is excessive. The corner partition is also uninsulated. The is a lot of unnecessary framing material around the window and the window header should be insulated to R-5.

As far as the insulation

As far as the insulation contractor is concerned, I think everything has pretty much been hit. To expand a bit, the framing contractor is not free of blame here either. It is tough to tell the exactly from the picture, but the framing contractor did a few undesirable things related to energy efficiency as well:

1)Double sill underneath the window. This is completely unnecessary structurally, and just creates one more area for unnecessary airflow.

2)Triple king stud on the left side of the window. This is structurally unnecessary under almost any circumstance, and especially this situation considering the orientation of the trusses. (In a load-bearing situation, if anything should be doubled, it is the jacks, as they are carrying the header, and therefore the subsequent load above). I can understand the temptation to throw the extra stud in there being as though it I so close to the corner, but there are much more desirable ways to do it. This orientation replaces area that could be insulated with unnecessary wood, and again creates unnecessary voids for air to flow through.

3)The framing orientation appears to completely block off the corner, creating a void that the insulation contractor can’t get to (not that he likely would have anyways).

There are a few other less than desirable framing methods that could be discussed, but these appear to be the major and obvious ones. None of this is the end of the world (especially if you have a descent insulation contractor), but just creates a few more unnecessary areas susceptible to airflow.

And this is almost all but guaranteed an exterior wall. The heels of the trusses landing on it are a dead giveaway.

I got it

The cotton candy is blocking the insulating paint.

(actually, is a vapor barrier required on the inside of the batt? I know you can use airtight drywall, etc. in many situations, but here?)

Log in or create an account to post a comment.

Sign up Log in