Image Credit: Images #1 through #5: BDA Keuringsinstituut - Kiwa NV

Image Credit: Images #1 through #5: BDA Keuringsinstituut - Kiwa NV The test assembly covered with a roofing membrane. The underside of the steel profile deck with a fastener after the test. This fastener is slightly corroded at its tip where it penetrated the roof deck, but that the portion of the fastener in sustained contact with the 2 inches of phenolic foam insulation is not corroded. The corrosion pattern for this fastener in the EPS insulation is very similar to the fastener in Image 4 (in the phenolic foam insulation). From the attic with two layers of Kingspan Kooltherm phenolic foam insulation, a fastener has been backed part way out.

Image Credit: Images #6 though #11: Peter Yost This is the same fastener that was shown in Image #6. The screw has been backed out all the way to show that there is no corrosion anywhere on the fastener. That's no big surprise, given that it is a baked enamel fastener that was only installed a few months ago. This wall mockup from the same project as the insulation job discussed in my previous blog (81 Chapin Street, Brattleboro, Vermont) was stored for several months in my garage, which tends to be quite damp because the garage slab is old, broken, and has no moisture barrier between it and the soil underneath the garage. A screw — a drywall screw intended for interior use, not galvanized or otherwise treated — from the wall mockup, showing no corrosion along its length. I backed out a couple of screws, dumped water into the fastener holes, and then reinstalled the screws. A week later, there was still no corrosion on the drywall screw. The title slide of a PowerPoint presentation by Dr. Jan Kosny of the Fraunhofer Institute: “Development of a Bio-based, Inexpensive, Noncorrosive, and Nonflammable Phenolic Foam for Building Insulation.”

Image Credit: Images #12 through #14: Fraunhofer Institute U.S.A. The rooftop of the test hut where 8 different types of phenolic foam rigid insulation underwent a corrosion test. These photos show the inside of the Fraunhofer rooftop test hut and show how water is delivered to the roof system to load the installed phenolic foam rigid insulation with moisture.

A particularly well thought-out and thorough question from longtime GBA reader Aaron Birkland on the pH of phenolic foam and its possible corrosive nature prompted me to follow up my original blog on Kingspan’s Kooltherm rigid insulation.

Aaron has two main questions:

- Has the issue of acidity and corrosion of fasteners or metal roof decks been solved with Kingspan’s Kooltherm?

- If so, is Kooltherm the only phenolic foam rigid insulation game in town?

Brief background

Phenolic foam rigid insulation was introduced in the U.S. in the 1980s and sold by Beazer East and Johns Manville, but serious corrosion problems resulted in legal action and both companies ceased production in 1992.

Kingspan, an Irish company with a completely new formulation for its phenolic foam insulation, has been producing and selling Kooltherm in Europe since 1992, introducing it in the U.S. in 2016.

The Dow report

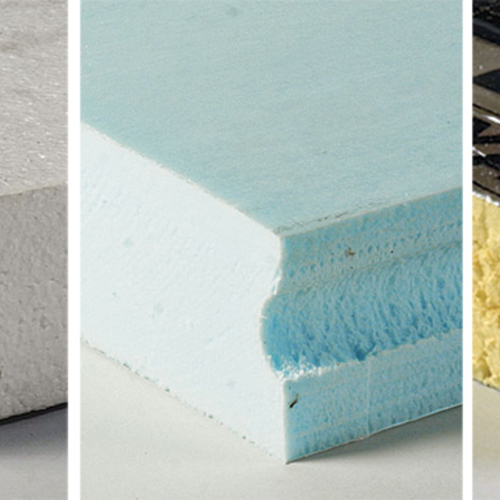

In 2012, Dow Building Solutions introduced a white paper, “Rigid Polymeric Foam Boardstock Technical Assessment,” at a Society of Plastics Engineers conference. This paper compares certain performance properties of two types of phenolic foam, one type of polyisocyanurate, and one type of extruded polystyrene (XPS) insulation. Here are the most important points from this paper:

- 1. Neither of the two phenolic foam board insulations mentioned in the Dow white paper is Kingspan’s Kooltherm.

- 2. The listed R-value for the phenolic foam boards is R-6.7 to R-7.5 per inch; Kooltherm insulation is R-8+ per inch. (Since the cellular structure of Koolspan’s phenolic foam is not uniform, the actual per-inch R-value of the insulation varies depending on thickness.)

- 3. The residual formaldehyde in the phenolic foam board discussed in the paper ranges from 137 to 253 parts per million (ppm). Kingspan has independent third-party data (testing conducted by the Fraunhofer Institute in Germany) showing residual formaldehyde at less than 0.15 ppm. (One difficulty is that as a Europe-based company, Kingspan does not yet have U.S. standardized test results.)

- 4. The paper reports pH results per ASTM 971 for phenolic insulation A of 2.7 and for phenolic insulation B of 2.0 (quite acidic). Kingspan claims that Kooltherm tests yield pH in the same range as polyiso – 3.8 to 4. Again, the lack of third-party ASTM results is a current issue that Kingspan is working on with U.S. testing agencies.

Dr. Jan Kosny of Fraunhofer Institute (see last section of blog) is a widely respected building scientist and materials expert; Kosny characterized this Dow report as “marketing material.”

Kingspan provided me with a third-party pH test of their Kooltherm insulation conducted by Cardiff University, dated July 21, 2010, following the test method for EN13468: “Thermal insulating products for building equipment and industrial installations – Determination of trace quantities of water soluble chloride, fluoride, silicate, and sodium ions and pH.” Two samples of the insulation yielded pH test results of 6.51 and 6.49.

Kingspan’s BDA Keuringsinstituut test report

Kingspan shared a test report with me prepared by BDA Keuringsinstituut (a division of Kiwa NV, a Netherlands-based testing laboratory), dated January 22, 2010. I do not have permission to copy or post this full report, but below is information from the report.

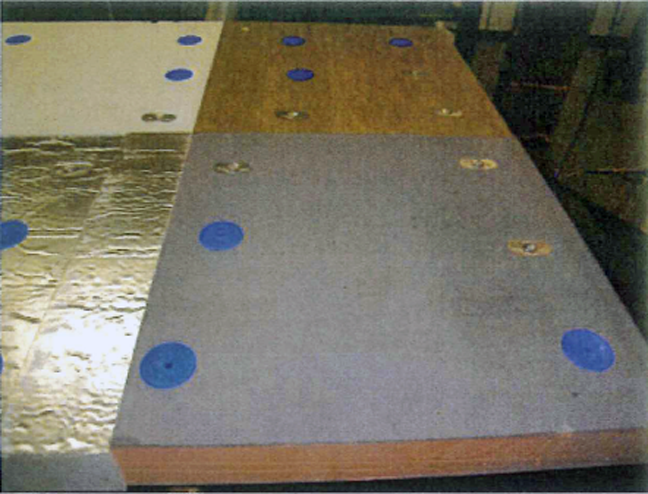

For the BDA Keuringsinstituut tests, four types of rigid insulation — mineral wool, Kingspan phenolic foam, polyurethane (PUR), and expanded polystyrene (EPS) — were fastened with washers and screws to a profiled steel deck (see Image #1, above) and the insulation then covered with an EPDM roof membrane (see Image #2, below). These assemblies were then placed over a heated water tank such that the assemblies were subjected to 70°C (158°F) and 95% relative humidity for 28 days.

To see the condition of the fasteners after testing was complete, see Images #3, #4, and #5 below (all photos taken from the report).

From the “Results” section of the report: “….[I]t appears as though there is no structural difference in the amount of corrosion after the test. All screws show on average the same amount of corrosion on the part of the screw that has been turned through the profiled steel deck. On that part that has not been turned through the profiled steel deck and therefore was in direct contact with the insulation material no corrosion was found.”

I tried to contact Dow Building Solutions to get their response to the above BDA Keuringsinstituut report on Kingspan’s Kooltherm, but did not hear back.

My “Wingnut testing”

It dawned on me that I could go to the Kooltherm project right here in Brattleboro, climb into the unfinished attic, and back out some screws to see if there was any corrosion (see Images #6 and #7). The only problem is that those big bad-boy screws were protected by a baked enamel finish, and they have only been in place about 4 or 5 months.

I also remembered that for my blog on the X-Floc cellulose insulation installation system, we used Kooltherm in a wall mockup installed with plain old interior drywall screws (see Images #8 and #9). This wall mockup has been sitting in my quite damp garage for the last three months. There is still no fastener corrosion, so I decided to fill the drywall screw holes with water and put the screws back in (see Image #10). Image #11 shows the same screw a week later: no corrosion, for what it’s worth.

DOE Buildings Technology Office project on phenolic foam insulation development

I was not aware of the DOE Buildings Technology Office project until Aaron let me know about it: Development of a Bio-based, Inexpensive, Noncorrosive, and Nonflammable Phenolic Foam for Building Insulation (see Image #12). I checked in with the project partner, Atlas Roofing. They reported that there has been no commercialization of this work, either on their part or as evidenced by any new patents they could find based on this project (a key indicator of any project commercialization).

Just before completing this blog, however, I did reach Dr. Jan Kosny, Director of Building Enclosures and Materials at the Fraunhofer Institute U.S.A. Kosny reports:

- 1. This DOE project was completed in 2017. Currently Fraunhofer is being funded by DOE and working with Oak Ridge National Laboratory on corrosion field testing of a range of phenolic foam insulations, research that will be completed in 2019.

- 2. As part of the corrosion field testing, Fraunhofer has a rooftop test hut for 5 or 6 commercially available phenolic foam insulations as well as two new formulations (see Images #12 and #13).

- 3. Fraunhofer is independently continuing its work on phenolic foam insulation, a process that involves sustained multi-year product development (up to eight more years).

- 4. While Atlas Insulation is no longer involved in this product development effort, Fraunhofer is in serious and is engaged in confidential discussions with a number of other companies to continue phenolic foam insulation development.

Not surprisingly, these images (and the testing they represent) put my “Wingnut-testing” to shame.

Conclusions?

Kooltherm remains the “real McCoy” of currently available phenolic foam rigid insulation in the U.S.

Acidity concerns and corrosion issues have been resolved with Kooltherm phenolic foam rigid insulation. And while competitors to Kooltherm insulation may be several years out, Fraunhofer-led research and development could well mean serious competition in the years to come.

In addition to acting as GBA’s technical director, Peter Yost is the Vice President for Technical Services at BuildingGreen in Brattleboro, Vermont. He has been building, researching, teaching, writing, and consulting on high-performance homes for more than twenty years. An experienced trainer and consultant, he’s been recognized as NAHB Educator of the Year. Do you have a building science puzzle? Contact Pete here. You can also sign up for BuildingGreen’s email newsletter to get a free report on insulation, as well as regular posts from Peter.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

7 Comments

Sorry, Can't Help But Toot My Own Horn....

....when I scrolled down the past article and saw Post #41 ;)

"41.

FEB 8, 2018 12:11 PM ET

Of note may be why this product was previously discouraged in its use:

http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_08ab/0901b803808a...

"Phenolic foam insulation was manufactured and sold into the North American market in the 1980’s

and early 90’s, mainly as roofing insulation. Claimed benefits were high insulation value and excellent fire resistance. High moisture absorption potential and residual acid present in the foam allegedly resulted in significant corrosion issues. Class action lawsuits were filed against corporations in the early 1990’s. Past litigation in North America focused on corrosion allegedly caused by phenolic foam used in metal deck roofing applications. The resultant roofing failures and subsequent litigation are still fresh in the minds of the building community. "

Installation on the exterior or in high humidity areas (ie. bathroom) may require consulting the manufacturer of whether it is advised or not."

Excellent to know that this product doesn't suffer from that. Thanks for the follow-up!

Global Warming Impact?

Peter, Have you guys looked into/rated the global warming impact of Kooltherm? How does is compare to other types of rigid foam?

Thank you,

Response to Rick Evans

Rick,

Check out Peter Yost's first article on Kooltherm, "Kingspan Kooltherm Phenolic Foam Rigid Insulation." In that article, he reports that the blowing agent used to manufacture Kooltherm has a low global warming potential.

In a BuildingGreen article called "R-8 Phenolic Foam Boardstock Insulation Is Back," Alex Wilson reported, "The blowing agent is pentane, which has zero ozone-depletion potential (ODP) and a low global warming potential (GWP). Pentane is the same blowing agent used in polyisocyanurate (polyiso) insulation."

Cold and Aging?

Peter,

Great stuff! Is there any data on Kooltherm’s performance in cold climates? What about thermal drift over time?

I called Kingspan in VA a few months ago about a over-roofing

I asked them about using the Kooltherm product as exterior insulation on a roof deck and they told me it was not an appropriate product for that application. Unfortunately the person on the phone could not tell me why so I assume it doesn't have the compression strength required. Anyone else have experience with this? Their Winchester VA plant is only about 60 miles from me so I had hoped to use some of their product.

Thanks

It has been over a year since a new posting here re phenolic insulation. Kooltherm was the only commercially available product mentioned as available. Today I stumbled onto info re a factory opened in Japan in 2014:

March 13, 2014

Asahi Kasei Construction Materials Corp.

Asahi Kasei Construction Materials completed the addition of a new production line for Neoma™ phenolic foam insulation panels at its plant in Ibaraki, Japan, and held its opening ceremony on March 12, 2014.

It is anticipated that demand for high-performance thermal insulation material will increase dramatically due to growing consumer interest in “smart” and “zero energy” homes, as well as the Japanese government’s roadmap toward mandatory energy conservation standards for homes in 2020.

The new production line will enable Asahi Kasei Construction Materials to continue to meet growing demand for its flagship Neoma™ insulation panels as well as Jupii™ floor insulation panels. As Japan’s leading manufacturer of phenolic foam insulation panels, Asahi Kasei Construction Materials will continue to contribute to improved thermal environments in architectural works by further strengthening its operations while ensuring a stable supply of high-quality, high-performance products.

Outline of the opening ceremony

Date: March 12, 2014

Attendance: approximately 40

Notable Attendees: Mr. Taketsugu Fujiwara, President, Asahi Kasei Corp.

Mr. Tomihiro Maeda, President, Asahi Kasei Construction Materials Corp.

Outline of the new production line

Location: Sakai-machi, Sashima-gun, Ibaraki, Japan

(adjacent to the first Neoma™ production line)

Structure: Three stories above ground

Total floor area: 6,300 m2

Capacity: Increased to 1.8 times the present capacity (total for both lines)

Production: Neoma™ phenolic foam insulation panels,

Jupii™ floor insulation panels for wood-frame houses

Start-up: April 2014

Investment: approximately ¥4 billion

About Neoma™

Neoma™ is a family of phenolic foam insulation panels for houses, buildings, and industrial applications. It has received several notable awards in Japan, being recognized for its world-leading insulation performance, and has the leading share in the domestic market for external insulation of wood-frame houses.

About Jupii™

Jupii™ is a family of floor insulation panels for wood-frame houses, developed based on Neoma™ technology

I see that I have a username here, so I will add my name.

David Harris

Santa Rosa, CA

Asahi Kasei also produces AAC, autoclaved aerated concrete in Japan under license from Hebel, one of the two AAC brands held by Xella. Last announced ownership of Xella was 100% by Lonestar Funds.

Log in or create an account to post a comment.

Sign up Log in