Image Credit: Most photos by Peter Yost — Photo #2 by Frank Steiner — Photo #7 by Rich Misner

Image Credit: Most photos by Peter Yost — Photo #2 by Frank Steiner — Photo #7 by Rich Misner Like a bad house guest, this mold just wouldn't leave. There is a pretty good slope away from the structure. The gutters are good, but notice the water stains on the foundation. There is lots of foundation wetting associated with the leader disconnect. Note the approximate at-grade termination of the pretty skimpy exterior rigid insulation. The perimeter foundation drain leads to a nice drain-to-daylight termination, with steady flow still making its way from the structure. This firewood had a measured moisture content of 12.6%, significantly more than the 9.2% moisture content of the wood framing in the stairs adjacent to the firewood rack. (I did not think to measure the moisture content of the firewood outdoors, darn it). There is a range hood fan, but it’s a recirculating unit. There are a couple of easy ways to test the draw of an exhaust fan; the toilet paper test is one of them. Legend goes that 1-ply supported means about 25 cfm; 2-ply means 50 cfm. This photo shows the center beam in the basement. We're looking up at the center of the 1st floor framing (essentially, the bottom of the marriage wall). The triple 2-by on the left is for module 1, while the triple 2-by on the right for module 2. The space between the two is stuffed with fiberglass insulation. This is in the attic looking down at the top of modular unit 3 (on the right) with modular unit 4 on the left. (This is the top of the marriage wall). And there is the same fiberglass insulation stuffed between the two units. This is the top of the basement concrete foundation wall with the poorly insulated and not-air-sealed rim joist. Modular homes can be notorious for air leakage at the rim joist because of leveling shims used to level the first-floor units as they are set.

Author’s Note: I am setting up a series of building investigations that I have done over the years as puzzles, presenting successive pieces as an interesting way to tell the story. As with any story, you can read the end first if you want, but that approach cuts down on the drama (admittedly not a bad thing for some folks…)

“How do we know if someone really knows what the cause is? I’ve been dealing with mold for 20 years. We had mold in our previous house. My health has cost us so much financially already. Maybe the solution won’t be too expensive. Maybe it will be. I just want to know what the cause is and what to do about it so we can finally have this whole problem behind us.”

I lifted this quote directly from an email I received a couple of years ago, and sadly it’s not that unusual: homeowners frustrated with persistent or recurring mold after a wide variety of building practitioners of various stripes have rolled through, scratched their heads, and shrugged.

Let’s work through this puzzle pretty much how it played out.

Puzzle Piece #1:

Client: The mold is oddly only in certain closets and always down low, fading and thinning as you move from the baseboard up to about two or three feet (see Image #2, below).

Pete: The only practical way of getting rid of the mold is to manage moisture. I can help, but almost certainly I need to come and assess your home for moisture problems.

(Interlude as homeowner digests the cost and checks my qualifications…)

Puzzle Piece #2:

I drive up, and after introducing myself, immediately start walking the site looking at and taking pictures of bulk water management (see Images #3, 4, and 5) on the outside of the home. (It had rained long and hard the night before I showed up.).

Client: Why are you starting on the outside? The mold is in here.

Puzzle Piece #3:

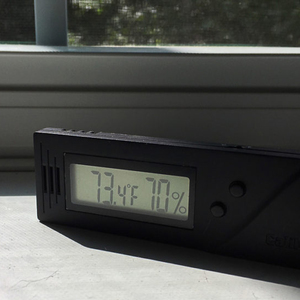

Pete: It’s pretty damp inside your home, given that you are still intermittently heating, you don’t have a whole-house ventilation system, and your home is closed up (mid-April, 10:30 a.m.).

- Outdoors: 59°F (dry bulb); 52°F (wet bulb); relative humidity 64%

- Basement: 56°F (dry bulb); 49°F (wet bulb); relative humidity 60%

- Kitchen: 65.5°F (dry bulb); 55°F (wet bulb); relative humidity 56%

- Upstairs (MBR): 68°F (dry bulb); 56.5°F (wet bulb); relative humidity 46%

Client: Huh, it doesn’t feel that damp to me; are those numbers high?

(Author’s note: we humans are pretty good at sensing dry bulb temperature, but notoriously lousy at sensing relative humidity).

Puzzle Piece #4:

Pete: Nice dual boiler (wood/fuel oil). How much stove wood do you normally store inside the basement for your boiler?

Client: We try to keep those 4 racks in the basement (see Image #6) as full as possible in the winter.

(Author’s note: one cord of wood can release as many as 800 pints of water as it dries inside a heated building).

Puzzle Piece #5:

Pete: Do you use your stove and oven quite a bit?

Client: Oh yes, we both like to cook and bake.

The oven has a range hood fan, but it’s a recirculation unit. No ventilation there. And burning 1 therm of gas releases about 1 gallon of water for unvented gas appliances or about 2.5 pints of water to cook a typical family dinner.

Puzzle Piece #6:

Pete: I just checked all the bath exhaust fans. The downstairs unit works fine (see Image #8), as well as the one in the upstairs bath, but the master suite bath exhaust fan does not work at all.

Client: You are making me nervous because I see a pattern developing here…

Puzzle Piece #7:

Pete: OK, it’s finally time to look at the mold.

Client: It’s funny, but the mold is in these three closets. It’s mostly these two on the first floor and then a bit of mold in the upstairs hall linen closet.

Pete: Huh — all three are along the central partition of your house. This is a modular home, isn’t it? (See Images #9, #10, and #11).

Puzzle solved?

Pete: Your home has high levels of moisture pretty much on all levels. In the winter, cold air is leaking in at your basement rim joist and being pulled up the home’s marriage wall, which — with just that fiberglass insulation — forms a highway for air to leak from basement to attic.

The first-floor mold pattern is caused by the cooler basement air bringing the surface temperature of your gypsum wallboard down below the dew point so that condensation forms. But as that cold air travels up, it gets warmed and the mold fades.

I think the mold in the upstairs linen closet (which is much less pronounced) is caused when it’s really cold and your wood boiler is going full tilt with the combustion air it needs pulling cold air down from the attic on occasion.

Client: Oh my word; this all sounds really expensive to fix.

Pete: It’s not nearly as bad as it sounds, really. Complete the action list below. Frankly, many (if not most) of these things you could do yourself.

- 1. Store as little firewood in your basement as you reasonably can.

- 2. Install an exhaust fan over your gas stove, running the exhaust duct through the top cabinets, exiting at the soffit — or you can run straight out to the rear wall of the house.

- 3. Replace the exhaust fan in your master bathroom.

- 4. Air seal:

- Rim joist (also properly insulate)

- Marriage wall opening in basement

- Marriage wall opening in attic.

- 5. Fix all connections of your gutter system.

- 6. Install a coating (exterior paint or Xypex) on the above-grade portion of your concrete foundation.

- 7. After air sealing, you should probably have a radon test done because sometimes air sealing can increase radon levels.

The mold problem has been eliminated

About a year and a half later:

Client: “We did everything you recommended to address the mold here. The mold problem has definitely been eliminated. We have not seen any more or new mold anywhere in the house. And it just feels better overall. It’s hard to describe how it feels better exactly but it does. I guess a word to describe it might be that it feels fresher in the house.

Pete: Sounds like money well spent, all things considered.

In addition to acting as GBA’s technical director, Peter Yost is the Vice President for Technical Services at BuildingGreen in Brattleboro, Vermont. He has been building, researching, teaching, writing, and consulting on high-performance homes for more than twenty years. An experienced trainer and consultant, he’s been recognized as NAHB Educator of the Year. Do you have a building science puzzle? Contact Pete here. You can also sign up for BuildingGreen’s email newsletter to get a free report on avoiding toxic insulation, as well as regular posts from Peter.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

7 Comments

Great article

Hi Peter, Very nicely written article with great info. I would love to see more of these types of case studies on GBA.

Fiberglass as sealant

I'm not sure what the original builders were thinking putting fiberglass in that crack. Did they really think they were accomplishing significant air sealing? Or is there some other reason for putting it there?

I have run into builders who have thought they could reduce air leakage but stuffing fiberglass into holes. I suppose it does reduce it a tad, but it's more useful as a way to tell when you are dealing with a builder who doesn't know how to air seal.

@Charlie

Perhaps the modular home builder thought the gap functions as a fresh air duct and they wanted to just filter the air instead? Ha

@ Charlie

I have a similar fiberglass in the cracks setup in my place, i pulled much of it out (some to still go) but that was "air sealing" in the 1970s on this house.

Fiberglass "Air Sealing"

There is a local replacement window franchise that advertises quite a bit on local TV channels that shows the installers jamming fiberglass between the opening and the window. This company charges roughly $1000/window and is doing a lot of business. The vast majority of home owners have no clue as to the details involved in construction - let alone advanced building performance - and rarely have an interest in becoming educated, so they explicitly trust whomever they hire to do whatever work as knowing how to accomplish "best industry practice".

Pete’s Puzzle: Mold in Certain Closets

WOW! that made my head sore.When will the world open their eyes to these experts with all their education and expensive equipment arrive with solutions that only applied in the dark ages.

If the "Consultants" were current in knowledge, they would have recommended that the old drafty house should be sealed and ventilated ASAP. Then either sell the property or completely rebuild with materials other than Wood Fibered products, ie. Concrete, Stone etc..

Response to George Hawirko

George,

An interesting theory, but one that doesn't hold water. Of course, Peter recommended that the house be sealed and ventilated, just as you suggested.

You should know that stone houses can be drafty and moldy, too, just like wood-framed houses. It's all in the details...

Log in or create an account to post a comment.

Sign up Log in