Image Credit: Energy Vanguard

When I woke up Saturday morning, the temperature outdoors was -40°F*. The wind chill was -100 degrees! It was just unbelievably, impossibly, inhumanly cold outside. Fortunately, that was on a mountaintop in New Hampshire and not where I was. I happened to have woken up on a mountaintop in North Carolina, where the temperature was a much warmer -3°F.

And when it’s cold outside, most people prefer to be in warm, cozy home with no drafts. Of course, we all know that no drafts means we have good airtightness, and good airtightness means we need mechanical ventilation. But how do you ventilate a home when it’s really, really cold outdoors without causing problems? And what are those problems with cold weather ventilation?

Three whole-house ventilation strategies

Exhaust-only ventilation. This one’s the cheapest to install and the most common. It relies on fans that are already in the home: bathroom exhaust fans and kitchen range hood. These fans are set to run continuously or intermittently with a controller. As they exhaust air from the home, the resulting negative pressure inside causes air from outside to come in through leakage sites in the building enclosure.

Supply-only ventilation. Like exhaust-only but the fans blow outdoor air into the house, creating a positive pressure. It can be done with regular bath fans or specially designed fans or by hooking up a controller to the central air handler.

Balanced ventilation. Most people automatically think of the energy recovery ventilator (ERV) and heat recovery ventilator (HRV) here, but balanced ventilation simply means supplying and exhausting equal quantities of air. I’ve written previously about different ways to do balanced ventilation.

When it’s really cold, bringing in outdoor air needs to be done with some forethought. There’s a reason we don’t just open the windows year-round. So let’s take a look at what can go wrong and what we can do to make things better.

Cold drafts

The problem. With any of the three strategies, you could end up with comfort problems if the occupants feel cold drafts. This can happen in a variety of ways. With exhaust-only, you could cause a draft through a leaky window or door near an occupied zone. With supply-only, you could be blowing untempered cold air right on occupants with a bad design. You could also use the central heating system to blow tempered air through all the vents in the home, but that air will feel cold to occupants, even if it’s close to room temperature. Same goes for ERVs and HRVs.

The solutions. This is mostly a design issue. Good HVAC contractors will tell you: Never blow air directly at the occupants. When ventilating with cold outdoor air, this is even more true. You want that air to be well-mixed by the time it reaches them. With exhaust-only ventilation, this is hard to do… and is yet another reason to avoid that strategy. Another aspect of this is the ventilation rate. If you’re ventilating more than necessary, this problem is more likely.

Dry air

The problem. Cold air is dry air. Air at 100% relative humidity sounds like really humid air, but when it’s at a temperature of 32°F, it’s actually pretty dry in terms of actual moisture concentration. If you warm up that same air to 70°F, the relative humidity drops to 20%. The colder it is outdoors, the lower the moisture in the air and the dryer your home becomes when that air comes inside, either through intentional whole-house ventilation or through infiltration. When you reach for that lotion, remember that the source of the problem is cold, dry outdoor air.

The solutions. Exhaust-only and supply-only ventilation with cold air will dry out the indoor air. That’s why indoor humidity runs lower in winter. In homes with a lot of air leakage, the indoor air can be bone dry. The same is true in homes with too much ventilation. Make sure you’re not ventilating more than you need to.

The question of how much ventilation you need is a big one, and one that I’ve addressed here previously. The standard answer is to ventilate at a rate specified by the ASHRAE residential ventilation standard, 62.2. The building code is diverging a bit from 62.2, and the rate in the 2018 International Residential Code (IRC) is:

(0.01 cfm/square foot of conditioned floor area) + (7.5 cfm/person)

For code purposes, the number of people in a home is defined as the number of bedrooms plus one.

But of course, what rate you choose depends on where you are in the process. If you’re building a new house, you have to go by your local code. If you’re living in a house with mechanical ventilation system, you can run it how you wish. You can use the formula above to get an idea of whether or not you might be overventilating. If the result of your calculation is that you need 50 cubic feet per minute (cfm) of ventilation air and you’re running your 200 cfm HRV continuously, I think it’s fair to say you’re ventilating more than you need to.

You also may be able to reduce the amount of ventilation air further when it’s really cold. Why? Because the stack effect increases with temperature difference. The colder it gets outdoors, the more infiltration you’ll have because of warm air rising inside the home. Some ventilation devices have controls that automatically cut down the amount of ventilation air when it’s cold.

Another way to reduce the drying effect of ventilating in cold weather is to use an energy-recovery ventilator. They exchange heat and moisture, thereby allowing you to keep the humidity levels higher. Instead of exhausting the humidity you already have and replacing it with dry air, some of the water vapor transfers across the membrane and comes back into the house.

And that brings up the next problem of cold weather ventilation…

Frozen ERV cores

The problem. I don’t live in a cold climate and don’t have direct experience with this, but if you talk to people in the really cold places, like IECC climate zones 6 and higher, some of them will say that you have to use a heat-recovery ventilator rather than an energy-recovery ventilator. The reason behind their claim is that when that water vapor transfers through the energy-recovery ventilator membrane, it encounters that incoming cold air and freezes. As the mass of ice in the ventilator grows, you lose not only the moisture recovery and heat recovery but also the ventilation air. Ice, as it turns out, is a pretty good air barrier.

The solution. I’m sure some people will tell me in the comments to this article about actual freeze-up cases. What I know is that frozen ERV cores don’t have to happen in cold climates. How do I know? Because the Cold Climate Housing Research Center (CCHRC) has done some research on it. They studied 14 houses with 8 models of energy-recovery ventilators in Fairbanks, Alaska, in the winter of 2013-14. None froze, even though temperatures got as low as -40. (I love that temperature! Or at least the interesting factoid about it.)

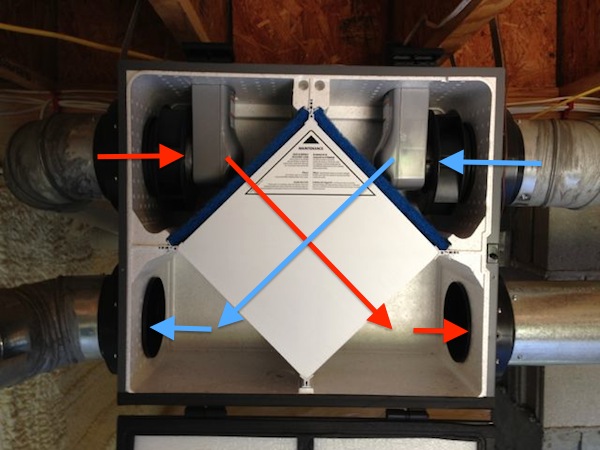

The solution is simple: a defrost cycle. Different models have different methods for preventing ice, so there’s not just one way to do it. Controls could close and shut off the intake side every once in a while, thus turning your ERV into an exhaust-only system temporarily. Similarly, the intake side could have a damper that switches from outdoor air to room air periodically. Another option is that the incoming air can be tempered with room air to keep the core above the freezing point. Frozen ERV cores aren’t a given in cold climates.

Condensation in walls

The problem. Water vapor likes cold surfaces. It will condense or adsorb on them with glee. (Or is it with gusto? I can never remember.) A supply-only ventilation system in a cold climate can result in positive pressures indoors, which can push humid, indoor air into wall cavities. When that humid air finds cold sheathing on the other side of the insulation, it starts accumulating. If enough accumulates over a long enough period of time, you can start a biology experiment in the wall. That’s bad for durability and for indoor air quality. I don’t recommend it.

The solutions. In warmer climates (generally zones 4 and lower), cold weather rarely lasts long enough for this to be a problem. In cold climates, this issue has garnered a lot attention because it’s real. It’s one reason some people recommend using exhaust-only ventilation rather than supply-only. That’s far from a guarantee against moisture accumulating in your sheathing, though. Those exhaust fans could be pulling air in down low while the stack effect is pushing it out up high. Joe Lstiburek has a great photo of a building showing moisture damage at the top of the building with no damage lower down.

The real solution here is fix the building enclosure. You can do that by installing exterior insulation that keeps the sheathing warmer or by keeping humid indoor air from leaking into the wall cavity.

Don’t forget the V in HVAC

Homes are getting a lot more airtight these days. New homes have to get blower door tests showing they hit certain thresholds. Older homes are getting air-sealed by home performance companies. That means we have a lot more whole-house ventilation systems in use. And no matter how it’s done, there’s technology involved. There’s design. There’s variation in conditions, both interior and exterior.

Buildings are put to the test when it’s really cold outdoors, as it has been recently with the ridiculously named Bomb Cyclone. (It sounds like a dessert at a chain restaurant.) Building enclosures fail. Heating systems fail. And ventilation systems fail. Things happen at really low temperatures that don’t happen when it’s a more normal cold.

If you’re experiencing any of the cold-weather ventilation problems I described above, the first step is figuring out where things went wrong. Was it the technology? The design? The installation? Knowing some building science can help a lot as you figure it out.

My hope is that eventually whole-house ventilation will be accorded the status it deserves. The initials HVAC seem to accord it equal weight to heating and air conditioning, yet that’s not currently the reality. But for now, I’m anxious to hear your cold weather ventilation stories and problems. What problems did I miss? What solutions have you found?

*Now really, I don’t have to give units for that temperature. Not because you already know it but because in the two temperature scales in common use, -40°F is equal to -40°C. Even the science nuts who insist on Kelvin know it’s impossible ever to reach -40°K because of the third law of thermodynamics. And the same is true of the Rankine scale, which is to Fahrenheit what Kelvin is to Celsius and for which you should not bother creating any neural connections. Therefore, it is never necessary to give units for the temperature -40°.

_________________________________________________________________________

Allison Bailes of Decatur, Georgia, is a speaker, writer, building science consultant, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

11 Comments

HRV Cold Weather Defrost Problem & Solution

I have an HRV that shuts off the input fan in order to defrost.

This has annoyed me for a few years now, as when that happens the house is depressurized and we suck in raw cold air from elsewhere. Since our home is very tight, most of that comes in through a little gravity damper in our mechanical room. However if I happen to open the door to our masonry heater (fireplace) during that same defrost cycle, a face full of fumes or ashes.

This last ridiculous cold spell spurred me to action.

I had noticed that the insulation on the fresh air input duct for the HRV was often waterlogged due to condensation. The insulation wasn't tight enough to keep moisture out. I have flirted with replacing that section of ductwork with a new duct and duct heater. This way I could slightly pre-heat the fresh air to prevent the condensation. It would also allow me to cut down the number of times that the HRV went into defrost. Unfortunately I never quite found the right duct heater, as my duct work sections weren't long enough to prevent turbulence before or after; the elements in any heater were likely to have uneven airflow over them and burn out.

The epiphany I had the other day was to remove the insulation and wrap the fresh air duct with an electric heating cable. So far this has actually worked quite well. The small amount of heat keeps moisture from condensing on the surface of the duct. Since this duct is now exposed to the warmer air of the mechanical room, the input air temp to the HRV is now slightly tempered/higher too, so the unit goes into defrost less often.

Pictures follow of the HRV input duct with insulation, images showing ice (!) under the insulation, and the duct with the electric heater cable wrapped around it.

If you look carefully on the upper right of the one image, you will observe that my little fresh air gravity damper is open and the manometer reading is zero. The HRV was in defrost when I took that picture.

Pix of the post installation HRV input (OA) and output (MA) temps also attached.

Allison,

Is that -40° from

Allison,

Is that -40° from north, or from the ships head? :)

Andrew,

I was faced with the same situation. I ended up buying a newer energy star qualified HRV that went into a recirc mode, moving conditioned air through the core and back into the house to defrost. Now I'm off to look at my HRV's performance curves to see what the "proper" speed should be.

Frost formation mechanism

My understanding of the frost formation mechanism is different than what Allison describes. I understood the problem to occur as the temperature of the outgoing air drops to less than its dew point and also less than freezing. As a result, moisture from the outgoing air freezes on the walls of the outlet channels. Allison's explanation would not explain frost in an HRV, but as the above two comments indicate, HRV's are also susceptible. Based on my understanding of the mechanism, ERVs are less likely to frost than HRVs because the outgoing air's dewpoint drops as it transfers moisture to the incoming air.

Renewaire ERVs do not have defrost provisions. I asked a Renewaire rep why they can get away without defrost. His explanation was that the moisture transfer was sufficiently effective that the dewpoint drops fast enough that the outgoing air temperature does not drop below the dewpoint.

Reply to Andrew Bater

Hi Andrew,

The problem with waterlogged insulation on the supply duct is a common one caused by the fact that the manufacturers of insulated flex duct typically use 2 mil poly as the vapour barrier. This is way too flimsy to withstand the installer pulling the duct through joist bays, etc and we end up with a perforated vapour barrier which allows moisture to reach the cold surface of the duct and form condensation.

I would like to hear some suggestion for how to best protect the vapour barrier during installation. I would suggest wrapping the duct in 6 mil poly. Perhaps one could use the leg of an old pair of blue jeans. A pair of old bell bottoms from the 70s would work best, I think. You couldn't use skinny jeans. They likely wouldn't fit over a 6" duct.

Regarding the defrost cycle, houses with wood burning appliances need to be equipped with an HRV (or ERV) that uses a recirculating style of defrost.

Duct Type & Insulation / Recirculating Defrost / ERV versus HRV

David, the "before" supply duct picture that I attached was probably deceiving; we didn't use the normal flex duct.

All our ductwork in and out of the HRV is actually rigid. I know that is atypical due to concerns about transmitted noise. You may be able to discern that we isolated the HRV by placing it on a vibration pad on a shelf.

The point about supply ductwork moisture ingress is still valid though. That insulation, while pretty carefully taped and sealed, apparently wasn't perfect and let in moisture. Before I went to the heat tape method, I did look briefly whether I could find dual wall insulated rigid duct in the 6" size range. It's out there, but not common.

Agreed also on the need for a recirculating style of defrost for any home where wood burning appliances are in use. That wasn't something I had any clue on when that HRV was purchased; defrost methods don't seem to make spec sheet bullet points.

Our ventilation discussions back at construction centered around whether we should do an ERV or an HRV. At that point the guidance seemed to be: ERVs hot climate, HRVs cold climate. I think we are all a little smarter about that now. Frankly our selection of an HRV was probably OK the first year or two, as we slowly got rid of all the construction materials moisture. Now though it would be nice to have an ERV, as I perceive it would prevent the house from drying out as much as it does.

Question for Andrew

You state: Agreed also on the need for a recirculating style of defrost for any home where wood burning appliances are in use. Just curious as to why? Air filtration?

Recirculating Defrost versus "Simple" Defrost

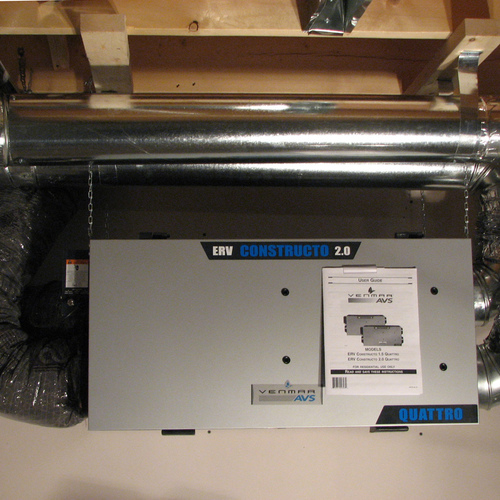

Jon, the HRV in my home is very similar (if not the exact model) to the one shown in the image at the top of Allison's article. At temperatures below freezing frost will develop on the core as the extremely cold outdoor air interacts with the warm humid indoor that is being exhausted. Here is the exact description of what happens to rectify that:

"The ERV and HRV units are equipped with an automatic defrost feature to eliminate any ice build up on the core.

• Automatic defrost is initiated once every hour when the fresh air supply temperature drops to 23°F (-5°C) or colder.

• The defrost cycle operates by turning off the supply fan while continuing to operate the exhaust fan.

• The exhaust fan speed is adjusted proportionally based on the outdoor temperature, initially operating at low speed.

• As the outdoor temperature continues to drop, the exhaust fan speed will increase, and will operate at maximum speed when the outdoor temperature is -4°F (-20°C) or less.

• The VNT5150 Series HRV/ERV defrost cycle runs for 4 minutes with the supply fan off, followed by 40 minutes of continuous normal operation.

• Defrost cycles will continue to repeat as long as the temperature is 23°F (-5°C) or less."

Our home measured less than .9 ACH50 when last measured for airtightness. It was the tightest home the rater had measured up to that point. It's probably even tighter than that now, as we had the Marvin rep here to adjust window seals, found a few more places to spray foam, etc. What happens when the HRV goes into defrost mode is that our home basically becomes depressurized. There are no holes or openings for the air that the HRV is exhausting to come from. It's almost like running a mini-blower door test.

During the aforementioned depressurization the "make up" air must come from somewhere. My first winter in the home this really surprised me; if I opened the door on my masonry heater to poke at the fire I would get a blast of fumes. Subsequent to that I installed a little relief damper in our mechanical room to minimize that problem. I also got better at building fires, no need to poke at them these days!

A recirculating defrost HRV or ERV would not cause this depressurization problem, as although it still uses warm inside air to defrost the coil, through some mechanism of dampers it keeps that air loop entirely within the building envelope.

By the way, you are right that there is an issue of filtering with the "simple" style defrost unit I have. The outside air that is sucked into the home during defrost depressurization either comes in through cracks in the building envelope or in my case through my little relief damper. Either way that air is not filtered. The good news is that typically outside dirt levels seem to be lower in the winter particularly if the ground is snow covered.

I recently upgraded my older 80% furnace to a 96% gas fired 2 stage furnace with two pvc direct vents run through the rim joist to outside for intake & exhaust. I'm cold climate zone 6a and I have a hard time understanding why two 3" vents that have no dampers that I'm aware of (unless There is a damper inside the furnace itself?) Arent letting in a overabundance of ventilation? I swear I can feel the temp difference in that room when the system isnt running. I've tried looking into it and it seems that these vents are correct in not having dampers? Is this right?

Tia,

The PVC intake and exhaust for your furnace is a closed system. They do not mix with the air inside your home.

With the intake and exhaust being close to each other, there is also nothing driving airflow through the pipes when the furnace is off (a potential conduction loss issue).

Supply-only seems like a good, affordable solution even in a cold climate like Toronto. Specifically, it’s an older home with a right-sized heat pump so the fan is almost always on. It would be a duct connecting the outdoors to the return ducts with a dampened control with a timer that’s “normally closed, powered open” so if it fails, it won’t result in over-ventilation. You can also adjust the damper so that open isn’t 100% open to commission the CFM. The duct will be insulated to reduce condensation risk. Are there any special consideration in this case? Does it matter where the ventilation connects to the existing return ductwork (i.e. how close it is to the central return grille and the air handler)?

Log in or create an account to post a comment.

Sign up Log in